With facilities that produce standard cable designs in masse, it has never been easier to find the right design. These mass-produced off-the-shelf cables may be able to meet some needs but they don’t allow for experimentation and are not suitable for more complicated applications. To fit new technologies, many industries will need more specific cable assemblies.

Generic models are less reliable and can offer inferior performance. Custom cable assemblies have superior design and performance. Made to order, custom cable assemblies provide reliability and greater returns on investment. These are five benefits to custom Cable assemblies.

Higher Quality

Cost restraints can often be a problem for mass-produced cables, wires, and connectors. This can have a negative impact on quality and durability. Cable manufacturers cannot produce the best quality cables because it increases costs and makes it difficult to sell them. Customers will be forced to choose cheaper alternatives.

You can control the quality standards and create products that meet regulatory standards with a custom Cable assembly manufacturer. Your custom cable manufacturer can test cables for specific parameters, such as their ability to withstand certain temperatures or operate in chemically-exposed environments.

Accurate Design

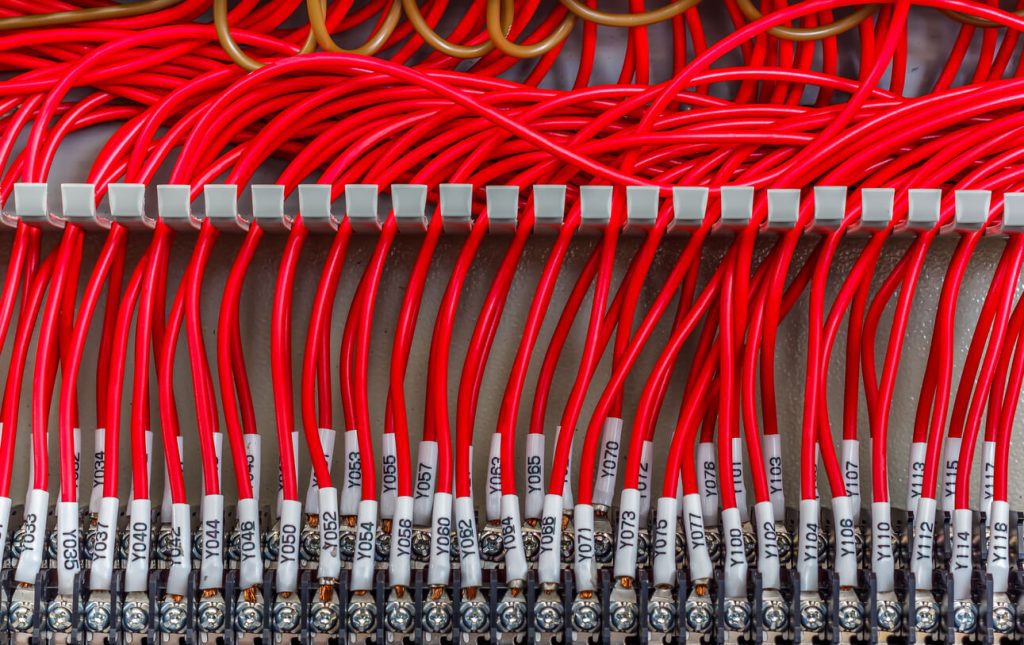

Because custom cables are made for specific applications, you can be sure you will get exactly what you need. It might not be possible to find standard cables that meet your needs if cables must be labeled or color-coded. These basic customization options are easily possible with custom cables. Our cables are also customizable to meet your exact needs.

Cable Quantity

Custom cables allow you to place bulk orders for large projects that require many cables. To avoid overordering or ending up with insufficient cables, you can be more specific with your order.

Superior Materials

The final result will be better if the materials are more precise. A standard cable may work in some cases, but a custom cable might be the best option. For cables to be protected and last longer, jacketing material and shielding are essential. For critical applications, such as those in the medical sector, it is important to control every aspect of a custom-made cable. These situations are critical and cables cannot fail prematurely. Custom cables can help you avoid this.

High-Tech Equipment & Testing Procedures

We are a top manufacturer of cable assemblies and use the most advanced technology.

- Our cable production includes inverter and high-voltage cables. We use wire cutting, crimping and stripping machines.

- A unique precision tool has been created to cut flat flexible cables into custom sizes.

- All products that we create are electronically tested for continuity, pin orientation, and other aspects.

- In our machine shop, we can design and manufacture custom fixtures and dies.

- All of our cable assemblies are made with UL & CSA-approved components