What is Tungsten Carbide?

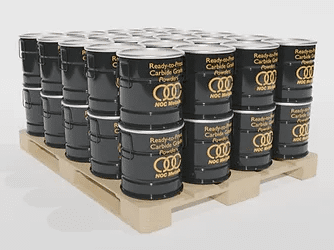

Tungsten caride, also called “cemented carbide”, or “hardall”, is a type of metallurgic material that contains tungsten Ready to press powder (chemical formula:WC) and another binder (cobalt, Nickel). etc.). It can be pressed into custom shapes and ground with precision. There are many types and grades available.

Tungsten Carbide Advantages

- It is well-known for its hardness and wear resistance relative to other metals. Tungsten carbide, which ranks at 9 on the Mohs scale and has a Vickers number around 2600, is very hard.

- The same properties will still be maintained even at temperatures below 500F

- Two times as stiff as steel with a Young’s modulus approximately 530-700 GPa (777,000-102,000 ksi)

- A tungsten carbide-made wear part has twice the strength of steel and is more durable than a steel tool.

Learn More about Tungsten Carbide

- What’s tungsten carbide? Why is it so popular for cutting tools and wear parts?

- Behind-the-scenes: How are tungsten carbide wear components made?

- 8 best carbide cleaning and packing tips

- There are 6 things you should know about choosing the right grinding jars to use with your planetary ball mill

- How can you avoid being “hurt” by poor quality tungsten caride materials?