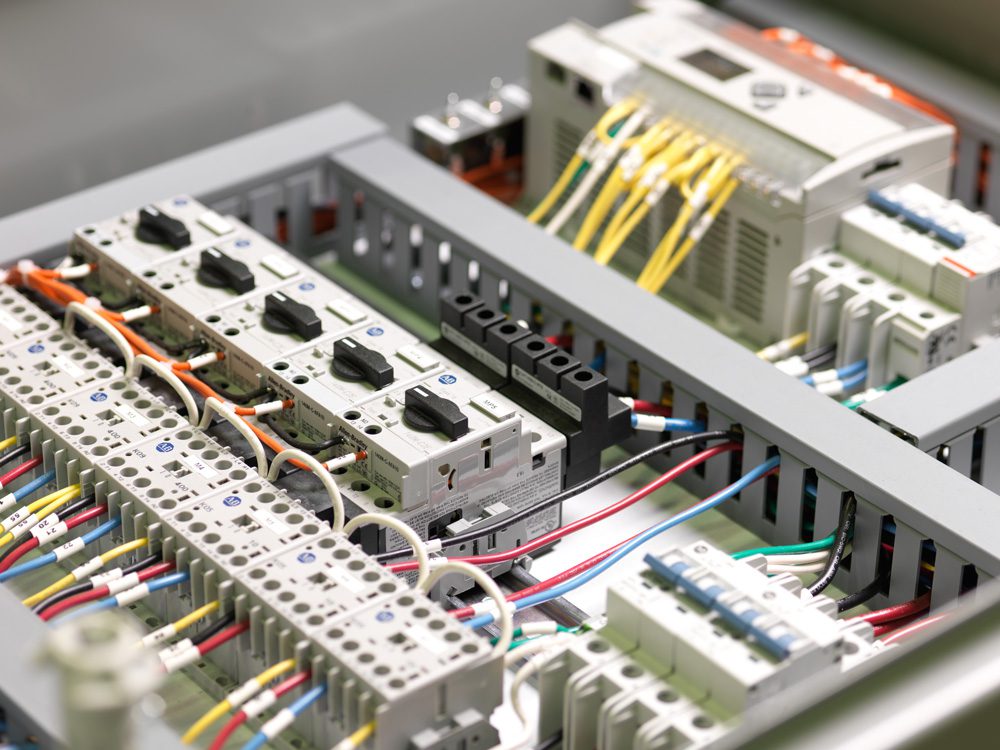

An box-build assembly or box build is an integrated system that is built around a printed circuitboard (PCB). The system may include wiring or enclosures, which connect the box-build to the next higher one and allow for the installation of subassemblies. You can add additional electronics or pneumatic devices to your PCB with a build box assembly. Many box builds include packaging and labeling the PCB within the protective housing. This includes the connectors and plugs that allow it to be plug-and-play when the customer takes it out.

YOU’LL SEE FAR FASTER TURNAROUND

Many services can take your 3DCAD model and make a working prototype with off-the-shelf parts. They’ll also be able to build it and ship it to the address you provide. Although they will need a bill and a blueprint, some EMS may be able create the box-build assembly process for your product by themselves. This can be made easier by providing a sample unit and a 3D model of your finished product.

RAISING MANUFACTURING FEES IS A SUCCESS

Outsourcing the design and/or manufacturing of box-build assemblies will reduce the price per item. EMS has the ability to take advantage of economies-of-scale, which allows you to pay less for wires, tie wraps and connectors than you would otherwise have to purchase in small quantities. Their employees are also familiar with testing and installing a variety of build boxes. This knowledge is more beneficial than a lower-rate production run for a new design. Read: Contract Manufacturing and Box Builds Client Case Study: Ronin

Electronic manufacturing services can be used to build your product. This means you will pay less per unit for changes to the design, or if they create custom designs that your customers request.

YOU’LL SEE A HIGHER QUALITY OVERALL

Outsourcing the production of box-build assemblies has many benefits.

- The electromechanical services that assemble many products are familiarized with each component they mount in your box build.

- Box builders who specialize in electromechanical assembly have more experience with housings and connectors than a house contractor. If you are looking to outsource your box build process it is important to ensure that they have the necessary experience to deliver optimal results.

- Assemblies houses can build many different box builds and know how to test each component correctly and make repairs.

- It is essential to work with an electronics manufacturer that guarantees system integration through full burn in tests. This will allow for better assembly processes.

Contractors can design the product and a process when they are familiar with aerospace or defense industry specifications. They are also able to test the products and label them according to strict specifications. It is possible for specialized contractors to assemble your PCBs into an electromechanical assembly and then put together the rest.

Six Ways to Shorten the Box Build Assembly Process

These are essential pieces of information that an Electronic Manufacturing Services (EMS), provider should know. This information can reduce the time required to build a box and allow for better quality electromechanical assemblies.

Product Dimensions

The dimensions of the unit include information about the size and weight of each component. This information gives the EMS all the information it needs to make decisions regarding how the units will be handled during the entire box build process. Dimension information can influence all aspects of shipping, storage, transport, packaging, as well as shipping.

Bill of Materials

A bill of materials is the most crucial piece of information that an Electronic Manufacturing Services (EMS provider) receives. This is also known as the recipe, formula, or ingredients list. The BOM allows the EMS to identify all the components and materials required for the project and what the client will supply.

Each item in a bill-of-materials has a purpose, procurement process, cost, and associated cost. The BOM should include details about item number, reference designer, part description and quantity.

A well-crafted bill to materials will help Electronic Manufacturing Services (EMS), provider, anticipate production delays and create alternative plans for the build.

3DCAD Model

The box building process is greatly aided by a visual representation of the final product. This visualization can be provided by a 3D CAD (3-dimensional computer-aided designing) model. Electronic contract manufacturers often use software packages that allow for 3D CAD design. These 3D CAD tools are also capable of converting computerized drawings into instructions, which can reduce the overall box building process.

Prototype / Sample Unit

An assembly of a product can be used as a physical tool for planning the box build. This is especially true when other information sources are not available. An EMS can quickly produce multiple identical assemblies from a customer’s rough prototype. An electromechanical assembly team with high-level skills can often reproduce a complete box build without any documentation other than the customer’s sample unit.

Test Use Cases

Customer should determine which testing must be done during box build assembly. Testing can be used for visual inspection, factory acceptance testing, or specific functional tests.

Safety is an important consideration when using any type of electrical device. The flash and earth bond tests are the basic testing methods for electrical systems. A seasoned EMS will guide you on what testing should be done during box construction to maximize production time and ensure a safe electromechanical assembly.

Shipping and Packaging Info

Electronics manufacturers can use this information to plan how the final box assembly will be packed and shipped prior to production. This information allows the EMS team to plan how the boxes will be managed during the entire box build process. It also optimizes box build speed.

IT SIMPLIFIES YOUR SUPPLY CHAIN

Electronics manufacturers work with clients to offer great service and invaluable expertise. They can help you streamline your design and make it more efficient. An electromechanical assembly house can reduce the complexity of your supply chain because they are the ones who build or buy chassis, cables and harnesses. There are EMS that have their own injection molding equipment and can make custom housings. This eliminates several cogs in the supply chain. The plastic housing is produced at the same location as the Box build services and wire harnesses. Some companies will hold subassemblies until they are ready for integration into higher-level assemblies.