Vacuum-insulated glass (VIG), an insulated glass that has a vacuum layer between two glass panes to maximize thermal efficiency and sound insulation, is called vacuum insulated glass. VIG is a thermally-insulating window technology that surpasses other insulating glass technologies (IG).

VIG technology is designed to meet the thermal performance requirements for net-zero energy windows.

This article will discuss the benefits and working of vacuum insulated glasses technology (VIG), in the construction industry.

Vacuum Insulated glass (VIG) Technology

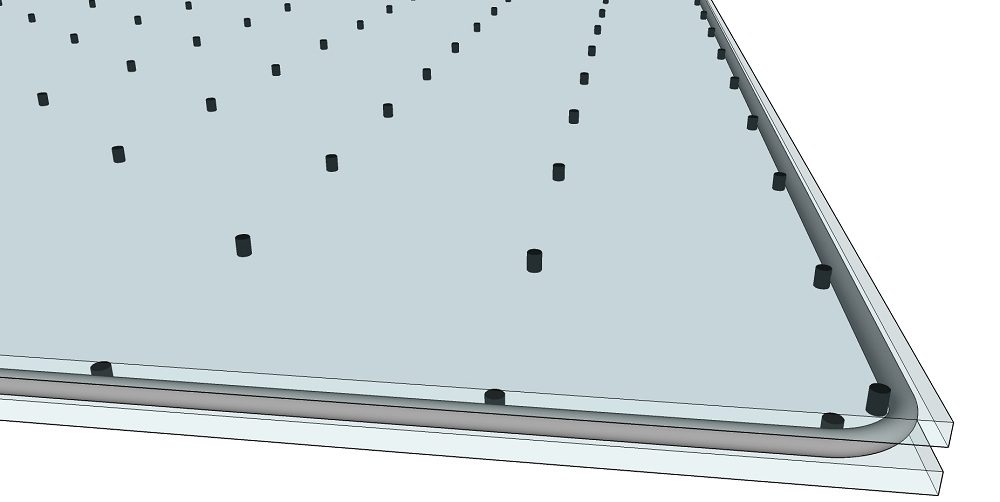

A VIG is made up of two layers of glass that are enclosed by a thin vacuum space. The space is usually about one tenth of an inch wide and has a pressure of 0.1 Pa. VIG is a unique insulating technology that encloses only vacuum between the glass panes. There are no gas molecules or air between the panes to transfer heat.

Features of Vacuum Insulated Glass

- VIG is a high-performance, deep-processed glass made from two pieces of glass and a vacuum layer between them. The one is white glass and the other is a LOW E glass. The vacuum layer is formed by fusion of the two glass panes. It can be sealed and held together with a thickness between 0.1 and 0.2 mm.

- VIG’s vacuum layer does not contain any gaseous or airy medium. Unlike other IG types there is no conduction medium or direct conduction medium. This principle increases the thermal resistance of vacuum glasses.

- VIG is made with a highly durable and efficient sealing technology that will keep the glass in good condition for longer periods of time.

- Vacuum glass units are extremely lightweight and thin which reduces the building’s load. It helps reduce the need for frame materials, particularly aluminum and PVC profiles. This can help to lower construction costs.

- A VIG unit with vacuum technology reduces the U value to 0.25 or less.

- The thermal insulation performance of vacuum glass is four times better than that of an insulating and six times better than that a single-layer glass. A VIG of normal size would have a thermal performance comparable to a concrete wall measuring 370mm.

- Because VIG contains vacuum, sound transmission can be blocked. Its sound insulation performance is approximately 10 dB better than normal insulating glasses.

- The VIG unit is very airtight and has no water vapor molecules. The unique arrangement prevents winter condensation.

- The VIG unit’s overall thickness is less than other types of window glass. It is therefore easier to design windows, especially replacements.

- VIG can be manufactured in customized sizes depending on your project needs.

- VIG increases the property’s thermal insulation and acoustic insulation. It has a positive impact on the energy consumption, which will lead to an increase in the property’s value.

- It’s used in hospitals, laboratories and renovation of doors and windows to save energy.

- VIG is expensive because of the small number of producers. They are well-worth the price for their long-term performance.

FAQs

What is vacuum-insulated glass?

Vacuum-insulated glass (VIG), an insulated glass that has a vacuum layer between two glass panes to maximize thermal efficiency and sound insulation, is called vacuum insulated glass manufacturer.

How does vacuum-insulated glass work?

A VIG is made up of two layers of glass that are enclosed by a thin vacuum space. The space is usually about one tenth of an inch wide and has a pressure of 0.1 Pa. VIG is a unique insulating technology that encloses only vacuum between the glass panes. There are no gas molecules or air between the panes to transfer heat.

What are the advantages of vacuum-insulated glass?

VIG increases the property’s thermal insulation and acoustic insulation. It has a positive impact on the building’s energy consumption, which will increase its value.